Memex Automation Becomes Member of the Premiere U.S Manufacturing Group AMT – The Association For Manufacturing Technology

BURLINGTON, ON–(Marketwired – Jul 31, 2014) – Astrix Networks Inc. (TSX VENTURE: OEE) operating under the trade name Memex Automation Inc., the global leader of manufacturing Machine-to-Machine (M2M) productivity solutions, is pleased to announce they have joined AMT – The Association For Manufacturing Technology.

Memex Automation, headquartered in Burlington, Ontario, specializes in networking machine tools to management information systems. “AMT is a recognized leader in the world of manufacturing in a number of significant areas. AMT drove the creation of MTConnect, the open and royalty-free interoperability standard for shop floor connectivity and over the past four years Memex Automation has played a key leadership role in developing the MTConnect community. We are very proud to be a member of AMT,” said David McPhail, President and CEO of Memex Automation. AMT also owns and manages IMTS – The International Manufacturing Technology Show, where Memex has been an exhibitor since 1992.

“Memex supported AMT programs and events even before joining. As members, I look forward to the opportunity to work with a high energy, innovative group of individuals to grow AMT and improve the programs they already use, like MTConnect, IMTS and the [MC]2 Conference,” said Patrick McGibbon, Vice President Industry Intelligence, The Association For Manufacturing Technology.

Dave Edstrom, CTO of Memex Automation knows AMT well. In 2006 he was part of a presentation at AMT’s annual meeting that lead to the creation of MTConnect. Edstrom became AMT’s Director for the Office of Strategic Innovation and served as President and Chairman of the MTConnect Institute. “I joined Memex because of its clear leadership position in MTConnect and driving productivity for manufacturing. It is with great pride that I can say Memex is a member of AMT,” said Edstrom.

About AMT – The Association For Manufacturing Technology

AMT – The Association For Manufacturing Technology represents and promotes U.S.-based manufacturing technology and its members — those who design, build, sell, and service the continuously evolving technology that lies at the heart of manufacturing. Founded in 1902 and based in Virginia, the association specializes in providing targeted business assistance, extensive global support, and business intelligence systems and analysis. AMT is the voice that communicates the importance of policies and programs that encourage research and innovation, and the development of educational initiatives to create tomorrow’s Smartforce. AMT owns and manages IMTS – The International Manufacturing Technology Show, which is the premier manufacturing technology event in North America.

For more information, please visit www.amtonline.org

About Memex Automation Inc.

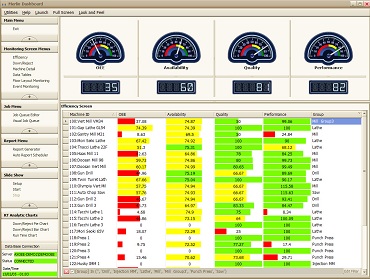

Memex Automation (TSX VENTURE: OEE) is the leader of manufacturing Machine to Machine (M2M) productivity solutions and the measurement of Overall Equipment Effectiveness (“OEE”) in real-time. OEE is the measurement of plant-wide capacity utilization. MERLIN (Manufacturing Enterprise Real-time Lean Information Network) generates OEE enterprise-wide, machine by machine. On April 15, 2014, PEM awarded the Company the 2013 Plant Engineering & Maintenance Award for Best Company Under 50 Employees. Frost & Sullivan awarded MERLIN its 2013 Technology Innovation Leadership Award for Machine Monitoring. Microsoft picked MERLIN to be its mid-market ERP machine connectivity solution. Mazak, North America’s largest original equipment manufacturer of machine tools, purchased MERLIN to manage its plant and now offers it on its price list. Okuma America Corporation, a world leader in CNC machine tools, announced in April 2014 that Memex Automation became a Partner in THINC.

For more information, please visit: www.memex.ca.

Contact Information

Memex Automation Inc.

John Rattray

VP Sales and Marketing

Phone: 905-635-0592

Email: Email Contact

market2world communications inc.

Paul Brent

Senior Communications Strategist

Office: 613-256-3939

Email: Email Contact

To see the full press release, please click here.