Control Costs with Shop Floor Monitoring

Taken from the Okuma Blog, Jeff Estes digs deeper into why machine monitoring is the key to finding where the productivity problems are so you can find and resolve them.

Profits can sneak out your door silently, unseen. But today we have tools that can help you determine where your productivity problems are, so you find and resolve them. The key is to perform shop floor monitoring and operations monitoring in addition to machine monitoring. By doing this you can view key performance indicators like parts output and quality – factors that are critical to measure so you can control your costs.

Dig Into Dashboard Data

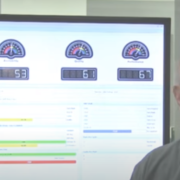

When a job takes longer than planned, you can spend a lot of time chasing people down to try and unravel the mystery about why this is happening. Or you can quickly find out where the problem is coming from in real time, from one centralized dashboard right at your desk. Check out this video to see how to use a shop floor monitoring dashboard to pinpoint issues that may be reducing your productivity. In our example, we see:

• An Overall Equipment Effectiveness (OEE) of 22%. (Yes, this is bad!)

• Performance is only 67%. (Why?)

By digging deeper into the dashboard data, clues emerge about these problem areas. Perhaps there’s an operator that needs more training, or there’s a problem with the material or process. Having a view of where the problem comes from allows you to solve it or prevent it. Shop floor monitoring tools like those available from Memex and dataZen (members of Partners in THINC) allow you to focus your energy in the right place, so you can increase your productivity.

How are you monitoring your shop floor? Feel free to comment below, or contact us, or your local distributor, to find out how you can use shop floor monitoring. And send us your ideas for future video blogs – we’re here to help!

Jeff Estes is Director of Partners in THINC, Okuma America Corporation.