Written by Dave Edstrom

What is the last metre?

The last metre, or last meter if you live in the United States, is the combination of technical, and sometimes business, challenges involved to make the final connection of a device to the Internet. A device would be any device from a multi-million dollar machine tool to an inexpensive sensor.

Many have heard of “the last mile problem” as it relates to the challenge of connecting a house to the Internet. Solving “the last mile problem” can be quite complicated and costly with legal right of ways, homeowner associations, and local politics and of course homeowner concerns. Solving the last metre is exponentially more complex because of the number and types of machines and devices on the manufacturing floor. At Memex, we know how to solve the last metre on the manufacturing floor and we know our methodologies and toolkits can provide the platform to solve the last metre problem in a variety of non-manufacturing industries.

Why is the last metre important?

As the old saying goes, the great thing about standards is that there are so many of them to choose from, and there are more standards coming every day. It is widely believed that only 2 to 3 percent of all shops or plants monitor their manufacturing floor. The reason for this very low number is the complexity and cost of connecting to the wide range of machine tools and manufacturing equipment. Without the ability to connect and get data from these devices, the ability to improve plant operations is completely stymied. When shops or plants are asked what their current utilization percent are, the number is typically 65 to 70 percent. When these plants are actually measured, the real number is 30 to 35 percent.

As Lord Kelvin so simply, yet elegantly stated, “you cannot manage what you cannot measure.”

Where and how is the last metre being solved?

With a wide range of protocols and expensive proprietary options, it has only been the largest of companies that have attempted to solve the last metre problem. Even then, these companies typically find out that it is much more costly and expensive than they initially planned. Too many companies end up with one-off solutions where they are forever locked into a very specific and usually expensive solution.

Memex Automation is solving the last metre problem in an open way that leaves the customer with choices today and choices tomorrow.

How does Memex Automation solve the last metre?

For 22 years, Memex Automation has been building a robust portfolio of products with the clear understanding of the last metre challenges. In order to address the plethora of machine tools and manufacturing devices on the plant floor, we created a sophisticated platform independent toolkit, made of software and hardware, with decades of experience in manufacturing that could be utilized to connect the millions of legacy machine tools around the globe.

The ability to connect to machine tools depends on how they are configured. With an MTConnect enabled machine tool, it is basically plug-n-play. For most companies, the most challenging connection is with a legacy machine tool. With a legacy machine tool, there likely is no MTConnect or OPC option, making connection a complicated task. However, at Memex, it’s a simple three-step process with the platform of software and hardware tools:

- We connect your machine tool to your network using a Universal Machine Interface (UMI).

- We connect the UMI to our “Signal Conditioner” software to interpret your machine’s information.

- We convert this information to the format you need, such as MTConnect, to make it easily readable and available on the network.

How does Memex Automation solve the last metre with devices that are not machine tools?

With our deep expertise with manufacturing and MTConnect, we know what needs to be done to convert other devices, protocols and systems using an adapter that will then send it to an MTConnect agent.

Does Memex Automation ONLY address the last metre?

Absolutely not!

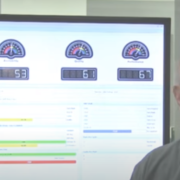

Memex provides a complete set of connectivity solutions for addressing the last metre challenge as well as a complete Manufacturing Execution System (MES) called MERLIN, as well as other hardware and software products to help manufacturing from the shop floor to the top floor. Memex has a communications platform to connect any manufacturing machine.

About Dave Edstrom

Dave Edstrom, CTO, was President and Chairman of the Board of the MTConnect Institute for the last three and a half years and prior to that, the Chief Technologist for Global Software at Sun Microsystems. In October 2006, while working at Sun Microsystems, Edstrom and Dr. David Patterson of the University of California at Berkeley, laid out the MTConnect vision at The Association For Manufacturing Technology’s Annual Meeting. Mr. Edstrom is the author of the book “MTConnect: To Measure Is To Know.”

The MTConnect standard is an open source royalty-free standard that is intended to foster greater interoperability between devices and software applications. By establishing an open and extensible channel of communication for plug-and-play interconnectivity between devices, equipment and systems, MTConnect allows sources to exchange and understand each other’s data. MERLIN incorporates the MTConnect standard in its universal machine interface, enabling all machines to communicate XML in real-time. MERLIN contextualizes the data to measure plant-wide capacity utilization in real-time.