Wearable Technologies Could Make Manufacturing Immersive Hyper-Experience

Popular media portrays wearable technology as a consumer trend with applications in entertainment and health and fitness. Possibly the best-known wearable technology is Google Glass, the head-worn device that can “augment reality” by displaying location-based and contextual information and taking hands-free photos and videos. Google’s promotion of the smartglasses targets a consumer audience, highlighting the device’s ability for enhancing lifestyles.

However, innovators are adapting wearable technology to business environments, including manufacturing organizations. Wearable technology holds application promise in such areas as production, warehousing, logistics, maintenance, safety, and security.

The smartglasses form factor offers usability benefits, says Dan Cui, vice president for business development at Rochester, N.Y.-based Vuzix Corp., which manufactures a device called the M100 SmartGlasses that is marketed to enterprises. “One thing about tablets and cell phones, versus something that you wear, is that handhelds are an acquired technology trait for humans,” he told ThomasNet News in an interview. “Wearing a headset is more suited to human physiology, as opposed to something you have to pick up and hold in your hands.”

Vuzix’s device is being used for warehouse applications, and the company is getting ready to release an application for field service.

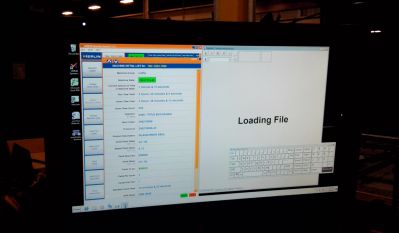

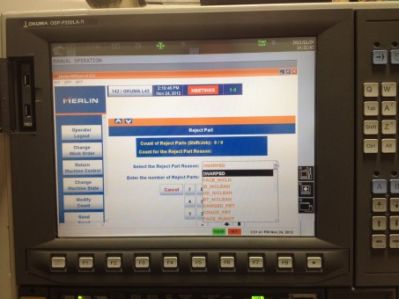

Wearable technology will increase in importance and improve in capability as the Internet of Things (IoT) continues to roll out in industrial environments, according to Dave Edstrom, chief technology officer at Burlington, Ont.-based Memex Automation. As machines become more intelligent and increasingly networked, more information about their operations and status will become available on the shop floor. The information cloud is creating an environment in which wearable technology can be of great utility.

That doesn’t mean it will be easy to pull off, Edstrom cautions, in speaking with ThomasNet News. “The ‘last-meter’ problem will become exponentially more important with wearables,” Edstrom said, referring to the challenge of capturing machine-generated data wirelessly and integrating it into the company network. “It will be expected that as someone walks around the plant, they can automatically gather data from any device that has a ‘digital heartbeat’ — provided they are authorized to,” he said. “It sounds easy, but the necessary steps to make that a reality are anything but easy.”

Implementing such a regime first requires the organization to structurally “know what is happening anytime, anywhere, on any device,” Edstrom said. “This means that the first step before wearables will be to make sure you are real-time-monitoring your plant. Only then does embracing wearables make sense.”

Indiana Technology and Manufacturing Companies (ITAMCO), a precision gear shop based in Plymouth, Ind., has developed a cloud-based app for Google Glass that allows a user to receive data from the manufacturing production environment over a network built on the MTConnect standard for machine communications.

Joel Neidig, technology manager at ITAMCO, told ThomasNet News that the company is using its Google Glass application in-house, refining the technology, and seeking partner companies that could benefit from the smartglasses in their own enterprises.

“We’re using it for monitoring machines that are in-cycle and for part-tracking,” Neidig said. The smart-glasses form factor “makes great sense especially in manufacturing,” he noted, since the plant floor is “where we all have to wear eye protection. Also, it’s nice to have something hands-free, because we’re always working with our hands.”

Neidig says the company is working on extending the app to materials handling, where he believes it could offer tremendous utility.

A video by ITAMCO demonstrates the capabilities and user experience of the company’s app. The video captures a walk-through of ITAMCO’s facility by Neidig while wearing Google Glass. The device displays environmental information for him, such as actual and target temperatures for the shop. Looking at a sprocket in the shop triggers a display of the corresponding part and operation numbers. Examining other parts, he is able to call up 3D models, manipulate the models using hand gestures, and view animated and exploded drawings.

When Neidig focuses on a machine, Google Glass delivers information about the machine’s status, utilization, and spindle speed via MTConnect. During the walk-through of the facility, Neidig is able to share photos and videos from the shop floor and communicate by video conference with a colleague.

While smartglasses constitute the best-known form of wearable computing, other form factors, such as clothing, textiles, and arm bands, also promise benefits. Emerging technologies include skin patches and even smart tattoos, or e-skin.

Speaking with ThomasNet News, Hubert Selvanathan, principal at Waterstone Management Group, an advisory firm focused on serving the technology sector, highlighted the potential of these other form factors. “Wearables could be helpful in monitoring ambient conditions to ensure safety on the shop floor or other locations,” he said. “A safety jacket could be outfitted with sensor technology to protect workers under hazardous conditions.”

Wearables could also take the form of authentication devices that restrict access within a facility, he suggests.

To see the full article, please click here.